SERVICE CENTER..

we solve any need and offer tailored services

processesprocesses

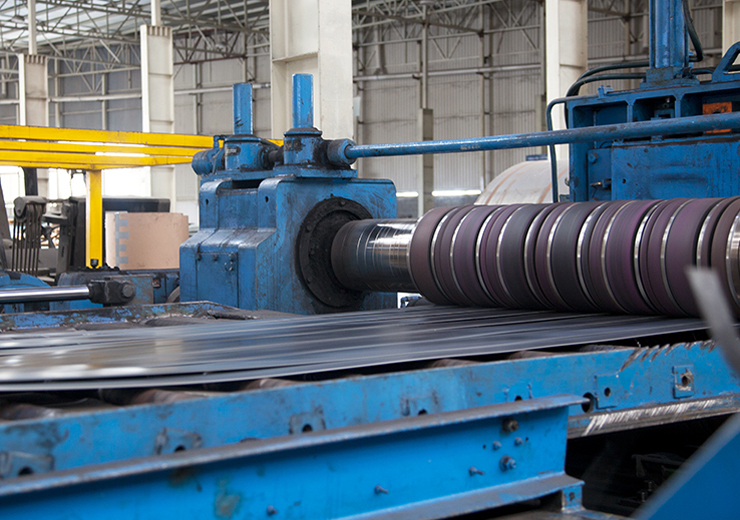

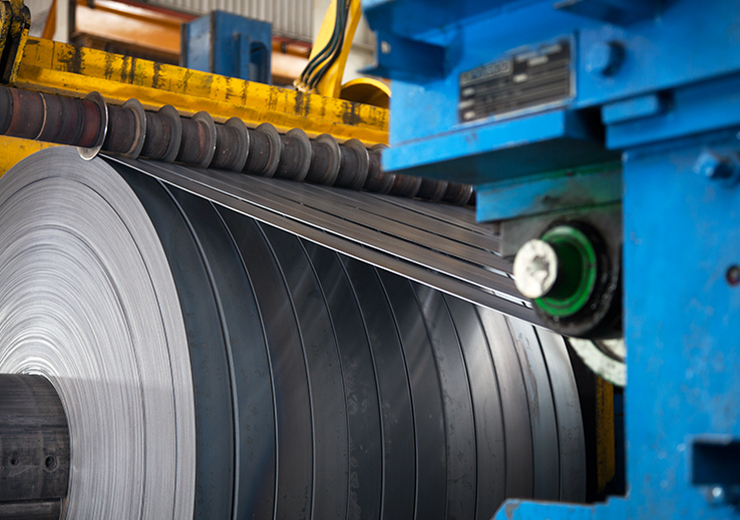

Longitudinal cut

(SLITTER) with Leveling

In CORTEACERO we have the Longitudinal Cutting service, with which you can obtain TAPES in a wide range of widths and thicknesses, and in turn, if the material requires it, apply a leveling to obtain a better surface appearance. Our SLITTERS help us to offer tapes with the tightest cutting tolerances on the market +/- 0.005 ”.

| Cienega Plant Capacity | ||

| Max | Min | |

| MASTER ROLL | 28 TON | 5 ton |

| CALIBER | 0.500” | 0.015” |

| WIDTH | 72” | 3/4” |

| San Nicolás Plant Capacity | ||

| Max | Min | |

| MASTER ROLL | 22 TON | 3 TON |

| CALIBER | 0.134” | 0.010” |

| WIDTH | 60” | 2” |

| General capabilities | ||

| Max | Min | |

| MASTER ROLL | 28 TON | – |

| CALIBER | 0.500″ | 0.010” |

| WIDTH | 72” | |

| GRADO | AR G100 | |

| * HIGH RESISTANCE UP TO 100,000 GRADE | ||

CORRECTIVE LEVELING

At Corteacero we use equipment with the highest technology to process material meeting your dimensional requirements. Our corrective levelers help to produce and obtain flat material, eliminating the internal stresses of it.

| General capabilities | ||

| Max | Min | |

| MASTER ROLL | 28 TON | – |

| CALIBRE | 0.250” | 0.010” |

| WIDTH | 0.72” | 2” |

| LONG | 240 | 6 |

| San Nicolás Plant Capacity | ||

| Max | Min | |

| MASTER ROLL | 22 TON | 3 TON |

| CALIBRE | 0.063” | 0.010” |

| WIDTH | 60” | 2” |

| LONG | 240 | 6 |

| Cienega Plant Capacity | ||

| Max | Min | |

| MASTER ROLL | 28 TON | 5 ton |

| CALIBRE | 0.250” | 0.060” |

| WIDTH | 72” | 6” |

| LONG | 240″ | 6″ |

MULTIBLANKING

In CORTEACERO we have the multiblanking process, which incorporates longitudinal cutting (slitter) and leveling and cutting along the length, in a single operation. With this we obtain the following benefits:

- Reducimos tiempo de proceso

- Reducimos el scrap.

- Se maneja menos el material. Esto es sumamente importante si se tienen superficies críticas en los blanks.

| General capabilities | ||

| Max | Min | |

| MASTER ROLL | 22 TON | – |

| CALIBER | 0.306” | 6” |

| WIDTH | 60” | 12” |

| LONG | 240 | 6 |

| CUTS IN 0.063” | 6 | 3 |

| San Nicolás Plant Capacity | ||

| Max | Min | |

| MASTER ROLL | 22 TON | |

| CALIBER | 0.134” | 0.010” |

| WIDTH | 60” | 12” |

| LONG | 240 | 6 |

| CUTS IN 0.063” | 6 | 3 |

The Stamping division is an area equipped to meet the needs of our customers in die-cutting processes in progressive, semi-progressive and manual modes through our equipment with operating capacities from 125 to 1600 Tons capable of processing HSLA, dual phase , among others.

Nuestras naves todas ellas equipadas con grúas viajeras para el manejo de rollos y troqueles con capacidades de hasta 36 toneladas pudiendo así manejar fácilmente rollos de 20 Toneladas que es lo que nuestras líneas de alimentación en prensas son capaces de manejar.

Our equipment has a QDC quick die change system, and our high speed presses (125 to 300Ton) (60 to 120 GPM) capable of handling high volume projects. Talking about dies of different types implies also talking about their maintenance, for which we have our own tool workshop, and a group of experienced toolmakers who allow us to carry out 100% of the maintenance at home. We are an IATF 16949 Certified company prepared and equipped to meet the requirements of the Automotive industry and also be able to meet the expectations of the HVAC, White Line, Industrial, Residential industry.

Show stamping capabilities

Hide stamped capabilities

CAPACITIES

Progressive teams

We have equipment for progressive processes with capacities from 125 T to 1600T.

- HIGH SPEED PRESSES

- 1 OF 125 TON.

- 1 OF 150 TON.

- 1 OF 250 TON.

- 1 OF 300 TON.

- 1 OF 400 TON.

- HIGHER TONNESS PRESSES EQUIPPED TO HANDLE HSLA STEEL AND ROLL WIDTHS UP TO 72 “HANDLING CAPACITY OF ROLLS UP TO 20 TON.

- 4 OF 1000 TON.

- 1 OF 1600 TON.

Tandem equipment

We have equipment for tandem processes from 600Ton. up to 1000 Ton.

- WE HAVE A TANDEM LINE OF 5 EQUIPPED QDC PRESSES

- 1 OF 600 TON.

- 4 OF 1000 TON.

Stamping Ships

- EQUIPPED WITH SCRAP REMOVAL SYSTEM. (SHAKERS, SCRAP CONVEYOR WITH SCRAP REMOVAL TRAILER LOADING TOWER)

- TRAVELING CRANES IN EACH VESSEL WITH A CAPACITY OF 32 TON.

- ACCESS FOR LOADING AND UNLOADING TRAILERS.

Tool room

- LARGE AREA FOR DIE MAINTENANCE

- DIE MAINTENANCE 100 IN HOUSE

- 32 TON TRAVELING CRANE. WITH DOUBLE HOOK

Metrology Laboratory

- WE HAVE A CMM COORDINATE MACHINE BRAND: STARRETT DE MEASURES 84 ”X48” X 32 ”

- CHECKING FIXTURES STORAGE AREA

- MEASURING EQUIPMENT

- RESULTS ANALYSIS SOFTWARE

Human resource:

- We have qualified personnel with extensive experience to manage projects from the stage of prosecution, development, implementation and start-up of projects for different industries.

- AUTOMOTIVE

- HVAC

- WHITE LINE

- INDUSTRIAL

- RESIDENTIAL

Logistics Team

- We have equipment to manage the logistics concept in the required modality (EXWORKS, FOB customer’s plant)

Roll storage area

PT storage area

LASER CUT

At CORTEACERO we offer the LASER CUTTING service with FIBER, which is more efficient and faster than conventional cutting. With this we seek to obtain more precise pieces, with better quality in the cut. In turn, the equipment has a large bed of 2m x 6m, which helps us reduce times, have less waste and obtain more efficient nesting combinations which gives us better appearance, better performance and faster cutting times.

| General capabilities | ||

| Max | Min | |

| CALIBER | 2.00” | 0.063” |

| WIDTH | 95” | – |

| LONG | 240 | – |

CNC precision DOUBLE

At CORTEACERO we have the CNC precision BENDING service, which is used to form and bend metal sheets into different shapes, including U-shaped, V-shaped and channel-shaped parts and assemblies. The process involves the use of a hydraulic press to bend sheet metal at specific points to meet exact specifications. With this, we can design and manufacture high-quality parts and components, and with close tolerances.

| General capabilities | ||

| Max | Min | |

| CALIBER | 500” | 0.010” |

| WIDTH | 120” | 2″ |

| LONG | 300″ | 2″ |

Shearing

In CORTEACERO we have shear cutting for sheet and plate. With our equipment you can produce straight cuts, without burrs and with close tolerances in thicknesses of up to ½ ”.

| General capabilities | ||

| Max | Min | |

| CALIBER | 0.500” | 0.010” |

| WIDTH | 120” | 2″ |

| LONG | 300″ | 2″ |